How to utilize VOC 120% using a CTQ Tree 【Excel Template Practice】

Once we have collected voice of customers (VOC), we would like to utilize those feedback in business improvement. A powerful tool for that is the CTQ tree. With the CTQ tree, you can convert VOCs into CTQs (Critical To Quality) required for business improvement. You can put it into practice immediately with the CTQ tree template.

(Duration: 4:24)

DOWNLOAD ← Click this to download the “CTQ Tree” template file.

<< Related Videos >>

- CTQ Tree Case Study: Convert Customer Needs to CTQ, Critical To Quality【Mentoring Program】

- Lean Six Sigma has to start from Voice of Customer: VOC 【Excel Template: VOC Matrix Diagram】

- DMAIC: Measure Phase – How to set your project’s KPI (CTQ)【Benchmark】

- Introduction of the CTQ Tree Tool

- How to use the CTQ Tree template

- The 1st step is to identify critical customer needs.

- The 2nd step is to clarify the Quality Drivers of each customer need.

- Excel Tip 1: Copy shapes very easily and quickly

- Excel Tip 2: Connect a line and a shape

- Excel Tip 3: Align and distribute multiple shapes

- The 3rd step is to identify your CTQ (Critical To Quality) of your customer needs.

Introduction of the CTQ Tree Tool

Hi, this is Mike Negami, Lean Sigma Black Belt.

In recent videos, I’ve often talked about CTQ (Critical To Quality). For deeper understanding, I would like to introduce a very powerful tool, the CTQ Tree.

<< Related Videos >>

You are supposed to convert your VOC’s (Voice Of Customers) to CTQ at the beginning of the Measure Phase. This CTQ Tree will assist you in making the process very easy. I’ll explain how to use the CTQ Tree with an Excel template.

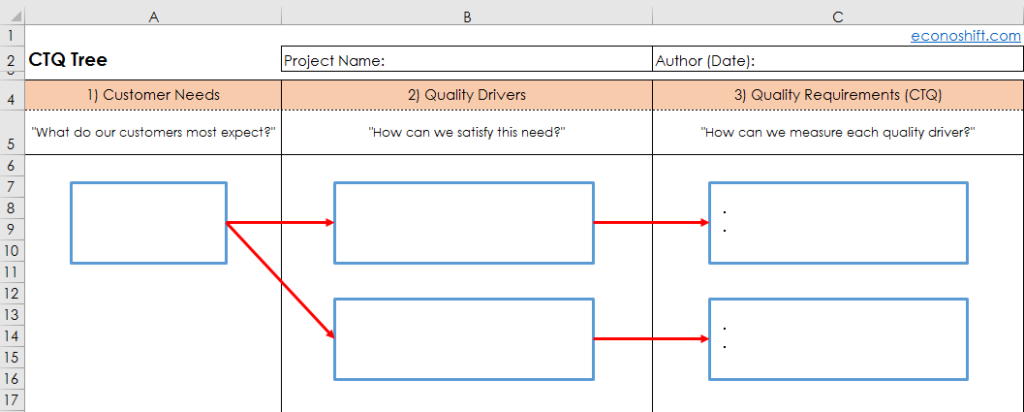

This is the actual template. You can download this template from below:

DOWNLOAD ← Click this to download the “CTQ Tree” template file.

How to use the CTQ Tree template

You’ll fill out the sections from left to right.

The 1st step is to identify critical customer needs.

It’s a good idea to ask your existing customers, “What do you most expect from this service or product?” Also, gather employees who are close to your customers, such as sales, customer service and marketing people and make them have a brainstorming session.

Let’s say that our most critical need is “On time delivery”, then type that here.

The 2nd step is to clarify the Quality Drivers of each customer need.

The next consideration is what things can we do to satisfy that need? We call those things quality drivers. In the brainstorming meeting, ask this question: “How can we satisfy this need?”

In this step, rough ideas are ok. Write down all the ideas your group came up with. After running out of new ideas, select only the practical ones. For our example, we’ve got three ideas. I’ll type them in Column B.

Excel Tip 1: Copy shapes very easily and quickly

There is no text box for the third one, so while pressing your shift key, select the arrows and text boxes. Then while pressing your control key, drag the images and release your mouse. You can copy them at the same time.

Excel Tip 2: Connect a line and a shape

Drag an edge of this line close to another shape. You’ll see black points on the shape. Releasing your mouse on one of the black points changes it to green. Then the box and line are connected.

Excel Tip 3: Align and distribute multiple shapes

Here is another Excel tip: You can very easily align and distribute multiple shapes this way. After selecting multiple shapes with your shift key, click “Drawing Tools’ Format”, “Align”, and then select “Align Left”. Again in the same “Align”, select “Distribute Vertically”. It looks better now.

I‘ll do the same in the next Column. This is the completion of alignment and distribution. By using this tip, you can write a flowchart beautifully and easily too.

<< Related Videos >>

The 3rd step is to identify your CTQ (Critical To Quality) of your customer needs.

Lastly, take a deeper look at each quality driver and type the specific and measurable quality requirements in the next column. In your meeting, use this question: “How can we measure each quality driver?” The answers will be CTQ.

There may be multiple CTQ’s for some quality drivers. Also sometimes you don’t have any measurable factors. It’s ok to use non-measurable ones. You should put at least one CTQ for each quality driver. This is the completion of the CTQ Tree and our CTQ’s have been identified.

Today’s theme was the CTQ Tree by which you can convert your VOC’s to the CTQ’s that are required for process improvement.

I hope it helped you to better understand the CTQ concept. Thank you for viewing. If you like my videos, please click the “Subscribe” button.